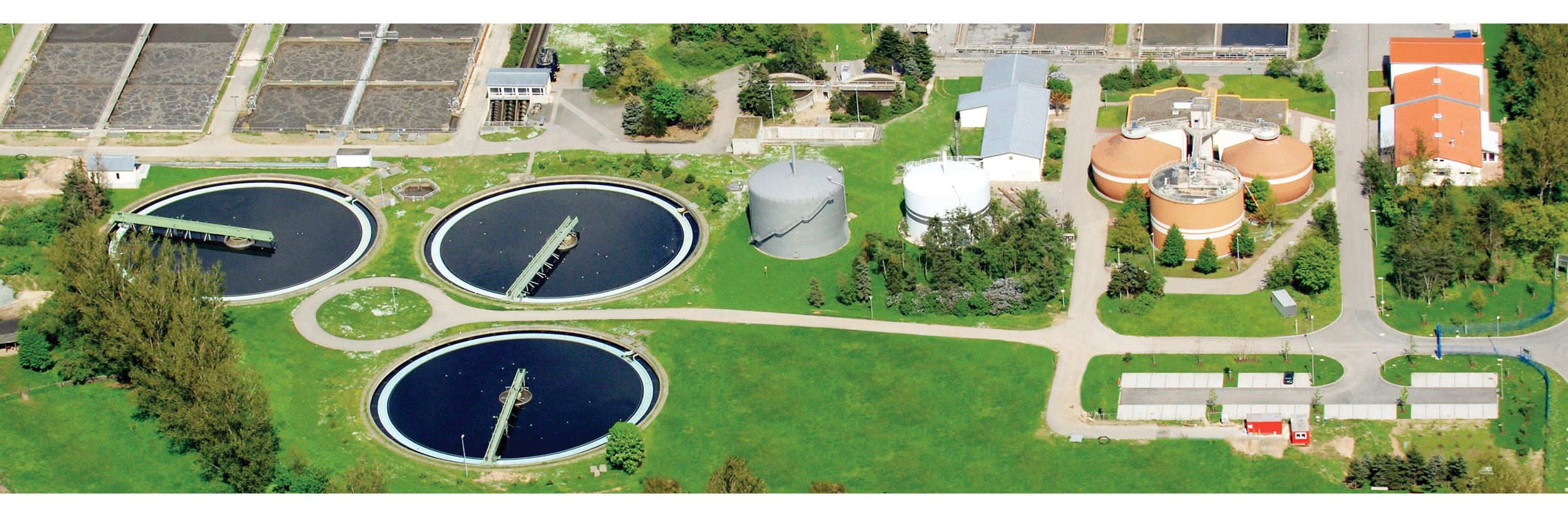

Advantages of ultrasonic technology at wastewater treatment plants

More electricity and less residual material, resulting in lower disposal costs!

With the integration of a high-performance ultrasonic system BIOSONATOR into existing systems of sewage treatment plants, the economic efficiency and the result of the sewage treatment plants are improved. By treating the sewage sludge with ultrasonic (sewage sludge disintegration), aerobic and anaerobic processes are intensified. This reduces the amount of residual sludge and at the same time produces biogas that can be used to supply energy to the plant.

ULTRAWAVES' high performance ultrasonic systems can be used in both municipal and industrial wastewater treatment plants for a variety of applications. These include primarily sludge treatment, but also wastewater treatment in the form of combating bulking sludge and foaming, as well as improved nitrogen elimination by providing internal carbon carriers.

BIOSONATOR: High-performance ultrasonic system for the treatment of sewage sludge

The efficient ultrasonic unit was developed as a plug & play system to test initial trial runs at wastewater treatment plants before the purchase decision is made. Before municipal and industrial wastewater treatment plant operators decide to use ultrasonic to treat their sewage sludge, even in the long term, the technology is usually tested in advance for several months. In order to now offer operators an even more practical and, above all, optimized solution, ULTRAWAVES, in cooperation with its colleagues from SONOTRONIC, has further developed the ultrasonic system into a plug & play system, the BIOSONATOR.

Because the peripherals, consisting of pump, pipework and flowmeter, are incorporated into the BIOSONATOR compact and are ideally matched to the ultrasonic unit, the technology can, from now on, be simply and directly integrated into current plant operation. The operator does not have to purchase any further equipment for the trial run, thereby saving time and cost.

Another significant advantage is that the ultrasonic system can be fitted with 100 % compatible components by our service engineers in less than one day and will demonstrate maximum effect even during the test phase. As the BIOSONATOR compact is divided up into three linked platforms (pump, ultrasonic system and switch cabinet), it is also simple to install in any room and is very easy to operate.

Ultrasonic disintegration has many applications at wastewater treatment plants

Ultrasonication can be used at many different layers in sewage treatment plants. Depending on the application, thickened excess or return sludge is exposed to ultrasonic waves, thereby bringing about, for example, increased biogas production, reduced amounts of residual sludge for disposal, reduced digestion time or even the rectification of operating problems. The positive effects of ultrasonic are established within a few weeks with the BIOSONATOR.

Where can the BIOSONATOR be used?

- Biogas plants

- Renewable raw materials plants

- Waste fermentation plants

- Cofermenter plants

- Plants with dry matter up to max. 15 %

- Wastewater treatment plants

What is the BIOSONATOR used for?

- Maximization of the biogas quantity

- Reduction of viscosity

- Stabilization of the biology

- Extending the life of agitators and pumps

- Reduction of disposal quantities and costs

What is achieved with the BIOSONATOR?

- Increase of gas production, up to 20 %

- Increase of methane content in biogas

- Savings in feeding

- Improvement of flow properties

- Substitution with cheaper substrates

- Reduction of disposal costs

- Reduction of own power demand

- Improvement of bioavailability

- Intensification of fermentation

- Increase of biogas production

- Savings in the purchase of substrates

- Feeding of alternative, rough, fibrous substrates

- Reduction of fermentation residues

Which goals can be pursued with the BIOSONATOR?

- Improvement of bioavailability in wastewater treatment plants and biogas plants

- Increase of biogas production

- Savings in the purchase of substrates

- Feeding of alternative, rough, fibrous substrates

- Reduction of fermentation residues

Applications Sludge Treatment

Facilitation of mixing of the fermenter contents

Conventional anaerobic digestion of sewage sludge is limited by the hydrolysis step (technical digestion limit). Treating (waste activated) sludge with ultrasonic overcomes this limit. The anaerobic digestion process is intensified and further degradation is achieved. This reduces the quantity of digested residual sludge, while biogas production increases.

The degradation of the organic sludge fraction in conventional anaerobic sludge stabilization is limited by the rate-determining hydrolysis step. Degradation rates of 50 % are rarely achieved. The reason for this is the difficult-to-access bacterial biomass of the excess sludge. This is broken down (disintegrated) by sonication with the ULTRAWAVES ultrasonic technology, and is thus more readily available for the subsequent biological-enzymatic degradation process.

Even at low energy inputs, ultrasonic causes a breakdown of the floc structure and the release of exoenzymes. This increases the interface between the solid and liquid phases and thus facilitates the enzymatic attack of the active microorganisms. Higher energy input leads to the disruption of bacterial cells, releasing cell contents and endoenzymes. These enzymes further accelerate the degradation process.

Increased production of biogas and reduction of the amount of residual sludge

The limiting hydrolysis step is overcome, the entire digestion process is intensified, and the organic fraction is further degraded. The main advantage of this is a significantly increased production of biogas and a reduction in the amount of residual sludge to be disposed of. As a result of the reduced residual organic matter, the dewaterability of the digested sludge is also facilitated (lower addition of flocculant) and increased (higher degree of dewatering). This disintegration of the sludge reduces its viscosity. This is important for operational practice, as it facilitates mixing of the digester contents, resulting in noticeable energy savings.

Digesters that are at the limit of their load can continue to operate without problems in the long term with the help of ultrasonic technology. In new buildings, the digesters could be sized with a lower retention time.

Wastewater treatment with ultrasonic

Generate chemical reactions with ultrasonic - without any chemistry!

In biological nitrogen elimination, carbon must be provided for the denitrification stage. Normally, methanol or other chemicals have to be bought in for this purpose. Ultrasonic breaks down bacterial biomass from the excess sludge. This makes the cell contents available as carbon carriers, which can be added to the denitrification process. At the same time, nitrogen degradation increases.

Nitrogen degradation

The biological nitrogen degradation takes place through nitrification and denitrification. A successful degradation process requires an additional carbon supply to be provided for the denitrification stage. Normally, methanol or another external carbon source is bought in and added to the process for this purpose. Sonication of the excess sludge with ultrasonic breaks down the biomass. This releases the cell contents – i.e. ideal carbon carriers –, which are then available as an internal source of carbon in the denitrification stage. Biological nitrogen degradation in the wastewater treatment plant can therefore be maintained or even intensified. If part of the sonicated sludge is returned to the biological phase, the quantity of sludge to be disposed of is automatically reduced. Use of ultrasonic for the degradation of nitrogen was successfully tested in practice and, for example, has been in operation in Bünde municipal wastewater treatment plant since 2006.

Environmentally friendly disinfection of contaminated water with ultrasonic

Ultrasonic can also be used for the disinfection of turbid and highly concentrated media, e.g. process water and wastewater, where the standard chlorine and UV methods fail. Germs attach to suspended particles or flocks and therefore easily escape disinfection by UV. Ultrasonic can be used to break down these agglomerations, so that the germs exist in isolation and resuspended. This makes them accessible to the classic methods once again, and they can be successfully attacked. Whether ultrasonic is used alone or in combination with conventional variants – effective disinfection is ensured.

Ultrasonic prevents bulking sludge and foams

Suppression of filamentous bacteria growth by the ultrasonic method

The creation of bulking sludge and foams due to mass development of filamentous microorganisms is a widespread problem in wastewater treatment plants. Foaming frequently also occurs in the digester as an independent phenomenon. Continuous sonication of a rather small partial flow of the return sludge by means of ultrasonic causes permanent stress on the active biomass in the activated sludge tank. We have demonstrated that predominantly filamentous bacteria are damaged by this permanent “ultrasonic” stress. As a consequence, the filamentous microorganisms are eliminated easily and reliably.

Seasonal bulking sludge problems often occur in wastewater treatment plants. These are usually caused by filamentous organisms. Foaming in digester tanks is also a familiar occurrence and can cause substantial operational problems. Sonication of a small quantity of the return activated sludge or returned excess sludge exposes this bacterial biomass to permanent stress through cavitation and fluctuating pressure in the liquid medium. ULTRAWAVES has proven that this process causes filamentous microorganisms to particularly suffer and therefore forces them to be permanently eliminated. Use of high-power ultrasonic can therefore prevent the formation of bulking sludge and stable wastewater treatment plant operation is maintained again.

References: Wastewater treatment plants worldwide in operation

The advantages of intensifying anaerobic sludge stabilization with ultrasonic

- Increase of oTR degradation by 15 % to 25 %

- Increase of biogas production by 15 % to 30 %

- Reduction of digestion time by 50 %

- Improvement of sludge dewatering by 5 % rel.

- Improvement of dewaterability of digested sludge by 5 % to 10 % rel.

- Increase in methane content by 2 % and thus increased electricity production

WWTP Ahrensburg

- Germany

- 50.000 residents

- since 2009

- Case study

- Press release, 2011 (German)

- Letter of reference

WWTP Arrudas

- Brazil

- 2.000.000 residents

- since 2010

WWTP Bad Lippspringe

- Germany

- 30.000 residents

- since 2019

WWTP Bamberg

- Germany

- since 2004

- First wastewater-based energy self-sufficient wastewater treatment plant in Europe

- Case study

- Letter of reference

WWTP Bünde

- Germany

- 54.000 residents

- since 2007

- Case study

- Press release (2006) (German)

- Press release (2007) (German)

- Letter of reference

WWTP Heide

- Germany

- 40.000 residents

- since 2016

WWTP Jockgrim

- Germany

- 21.000 residents

- since 2011

WWTP Ratheim

- Germany

- 45.000 residents

- since 2014

WWTP Ratzeburg

- Germany

- 34.000 residents

- since 2015

WWTP Shek Wu Hui

- Hongkong

- 350.000 residents

- since 2014

WWTP Trier

- Germany

- 170.000 residents

- since 2015

WWTP Yanzhou

- China

- 750.000 residents

- since 2016

The advantages of intensification of aerobic sludge stabilization

- Control of bulking and floating sludge

- Reduction of excess sludge up to 20 %

WWTP Leinetal

- Germany

- 55.000 residents

- since 2015

- Press release (2015) (German)

The advantages of intensifying anaerobic sludge fermentation/sludge and scum control

- Increase of oTR degradation up to 26 % and biogas production up to 26 %

- Elimination of foam problems and filamentous organisms in the digester

WWTP Meldorf

- Germany

- since 2005

- Case study

- Letter of reference

The advantages of bulking and floating sludge control

- Reduction of the sludge volume index SVI

- No floating sludge in the aeration tank

WWTP Schleswig

- Germany

- 60.000 residents

- since 2010

- Case study

The advantages of installations on distilleries

- Increase in alcohol yield by up to 20 %

Pearl Distillery

- Ongole, India

- since 2012

Contact