Ultrasonic

Environmentally friendly technology increases the efficiency and reduces costs

ULTRAWAVES' high-power ultrasonic technology makes it possible to cause disintegration of biomass by cavitation, whose released forces can destroy any robust surface.

Of all the plant technologies available on the market for disintegration by ultrasonic, the high-performance ultrasonic systems from ULTRAWAVES are the only ones that are capable of creating hard cavitation. Hard cavitation is the only means of achieving the breakdown of biomass agglomerates and an intensification of the fermentation process.

Ultrasonic Disintegration

Ultrasonic is sound with frequencies beyond the range of audible sound, i.e. from 20 kHz to the megahertz range. In aqueous media, ultrasonic waves cause periodic compression (pressure) and expansion (tension, negative pressure) of the sonicated medium.

High-intensity ultrasonic is necessary to tear apart water molecules during the rarefaction phase, which results in the formation of microscopically small voids in the liquid. These voids become bubbles filled with water vapor or gas. They grow in extension phases and shrink in compression phases, until they implode. This event is called cavitation, a process under extreme (adiabatic) conditions. On a microscale, pressures of 500 bar and a temperature of 5,000 °C are produced. Particularly large cavitation bubbles are produced within the frequency range from 20 to 100 kHz; when these bubbles collapse, they cause extreme mechanical shear forces. These forces produced by ultrasonic are capable of destroying even the most robust surfaces.

Effect on bacteria, algae and agricultural biomass

Disintegration of biomass in wastewater treatment plants

Disintegration of biomass in biogas plants

High-intensity ultrasonic causes biomass to break down. Our newly developed ultrasonic systems first decompose agglomerations of biomass material at rather low energy input (short sonication time). Further sonication opens up the biomass cells, so that the cell contents escape and dissolve. This process releases enzymes from the bacterial biomass. Hence, the sonicated biomass is readily available as a substrate for active microorganisms and is degraded better in a subsequent biological degradation process.

Biological degradation processes are intensified, i.e., the use of ultrasonic produces a greater yield of the end product and less residual materials. As a consequence of this, for example, in anaerobic sludge treatment, biogas production is increased and there is less residual sludge.

ULTRAWAVES High-Power Ultrasonic Technology

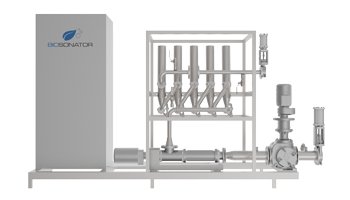

The standard ULTRAWAVES ultrasonic system is equipped with five oscillating units, consisting of a converter, booster and sonotrode. The number of oscillating units can be variably selected depending on the volumetric flow to be treated. Furthermore, it is possible to extend the number of ultrasonic modular systems used as required and therefore adapt to any plant size.

The ultrasonic components

Each oscillating unit is operated with a nominal power of 1 kW. However, in practice, this power is not permanently called upon. The extremely robust units usually run continuously (24/7). They are low maintenance; only the sonotrodes, which come into direct contact with the sonicated medium, are wearing parts and can be easily replaced.

How it works

Extensive empirical studies have led to the development of a patented high-power ultrasonic system, which is optimally tuned to the disintegration of biomass. Our ultrasonic reactors operate as a plug flow system. Ultrasonic within the lower frequency range (20 and 35 kHz) and high intensity is applied. Our ultrasonic systems can be used for volumetric flow rates of up to 2 m3/h, which means that the resulting sonication time for the medium is very short viz. only one minute. It is not necessary to recirculate the medium. The flow rate can even be higher for less concentrated suspensions.

- Inlet

Inlet of the biosolids through an upstream pump from the thickener (wastewater treatment plant). Feed of the biosolids through an upstream pump from the fermenter as a bypass (biogas plant). - Ultrasonic transmitter

Generation of the cavitation field in the biosolid by several ultrasonic transducers (oscillating unit = sonotrode, booster, converter) at 20 kHz. - Cavitation field

Splitting of organic cells, bacteria and fungi in the biosolids by high shear forces. Release of cell contents. - Pass

Looping of the biosolids through the ultrasonic reactor so that each floc is sonicated and passed through the cavitation field. Discharge of gas and air to the top. - Outlet

Discharge of the sonicated biosolids into the digestion tower (wastewater treatment plant). Returning the sonicated biosolids to the digester (biogas plant).

ULTRAWAVES high-power ultrasonic system BIOSONATOR

New design with variable number of modules

The patented ULTRAWAVES high-power ultrasonic systems have a compact design, and they increase efficiency in the production of environmentally friendly energy. Therefore, they can be easily and simply integrated into existing plants.

In the high-power ultrasonic system, the biomass strikes the front of the sonotrodes from left to right and is guided past them in loops. On the one hand, this prevents deposits within the individual chambers. On the other hand, the vibrating structures can work more efficiently and need less maintenance because the biomass does not adhere to the sonotrode tips. Thanks to the modular design, the new high-power ultrasonic system can be flexibly adapted to the size of the system. As a rule, it consists of three to five consecutively arranged modules – depending on the volume flow that is to be treated.

As the medium itself only dwells in the ultrasonic system for a short time, the unit has a very compact size. It can be easily integrated into existing plants via an inlet and outlet pipe, without any complications (plug & play).

Technical data

| Dimensions (l*w*h) [mm] | 1,330 * 750 * 1,500 |

| Weight [kg] | 120 |

| Volume [m³] | 0.030 |

| Connected load [kW] | 5 |

| Material | V2A steel |

High-power ultrasonic system BIOSONATOR

More output due to hard cavitation

However, nothing has changed in the process itself: of all ultrasonic disintegration systems available on the market, only the ULTRAWAVES high-performance ultrasonic systems are able to generate a hard cavitation. This means that the biomass is directly sonicated – in contrast to competing systems that vibrate the exterior of the container, similar to an ultrasonic cleaning bath. The biomass is first in their agglomerates split and then digested into other, smaller structures. These are later better bioavailable, which results in higher output. What nature, for example, usually requires 30 to 40 days on biogas plants, the high-power ultrasonic system creates in just a few seconds.

High-power ultrasonic system BIOSONATOR

Contact