Services

Our experience is your gain!

ULTRAWAVES accompanies you from the initial idea through to operation of your ultrasonic system. With our experience, our expertise and our efficient team, at ULTRAWAVES you are in the best hands when it comes to the use of innovative ultrasonic technology in environmental engineering.

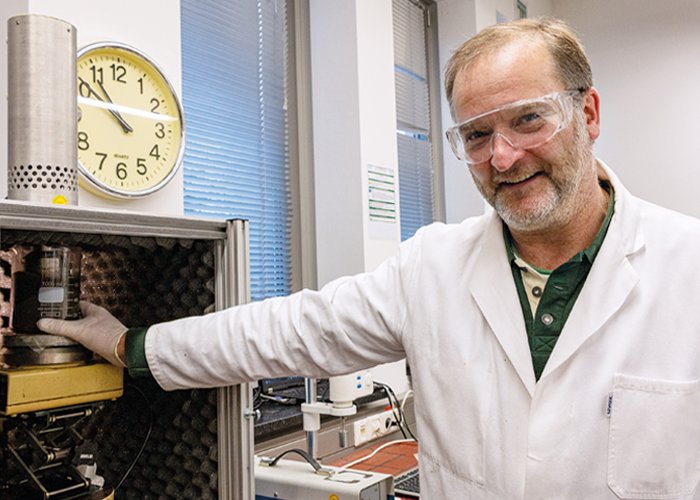

Research & Development

ULTRAWAVES pursues continuous practice-orientated research and development at our laboratory in order to further improve our ultrasonic technology and systems, and to find optimum solutions for our customers.

In our laboratory we routinely perform physical, chemical and biological analyses of the effects of ultrasonic. We research new application areas for use of our high-power ultrasonic systems and continuously improve the existing processes. We also perform specific tests for our customers and accompany you until the ideal solution has been found.

Consultancy

We discuss your project requirements and analyze your individual needs in consultancy meetings. This work is focused on increasing the efficiency and effectiveness of your plant. We exhaust all options to find optimum and flexible solutions for your application.

Training

We instruct users in proper intended use of the high-power ultrasonic system: They understand the principle and function of our ultrasonic technology and acquire application-oriented knowledge. You profit from our multidisciplinary knowledge of all kinds of different applications.

Analytical support

ULTRAWAVES offers accompanying analytical support and evaluation during use of its ultrasonic systems. Relevant parameters are determined, and therefore the efficiency increase achieved by ultrasonic is calculated.

Laboratory Tests

ULTRAWAVES has set up its own laboratory to satisfy specific requirements of its customers. As a result, we are able to provide you with reliable information on the effect of our high-power ultrasonic systems on aqueous suspensions (e.g. biomass, sludge) or other feasible applications in industry.

Our laboratory tests

This usually requires a preparation phase during which the appropriate samples are sonicated with variable ultrasonic energy input, in order to define the optimum ultrasonic setting for the planned practical operation. Our high-power ultrasonic systems normally operate with a frequency of 20 kHz or 35 kHz, as the required cavitation effect can be most effectively produced within this frequency range.

Ultrasonic

Accordingly, the following ultrasonic units are permanently available in our laboratory:

- Ultrasonic oscillating unit 20 kHz frequency, 1 kW output, 25-50W/cm2 intensity

- Ultrasonic oscillating unit 35 kHz frequency, 0.8 kW output, 60-120W/cm2 intensity

These oscillating units correspond to those installed in our standard ULTRAWAVES units. Special applications for fundamental studies require a wider range of frequency. To this end we are equipped with a range of laboratory ultrasonic units, which cover the wide frequency range between 40 kHz and 3,200 kHz (ELAC Nautik).

Viscosity

The sonication of all kinds of suspensions leads to a reduction in the suspension’s viscosity. This is often a very welcome effect, as the mixing in digester tanks or fermenters of biogas plants is significantly improved as a result. We use a rotational viscosimeter (Bohlin Instruments) to verify this positive effect.

Particle size distribution

Sonication causes a change in size distribution of the particles or flocks in suspensions. On request, we analyze the particle size distribution using a particle analyzer CIS 100 (Galai).

Methane potential

The AMPTS methane potential test system enables automated recording and evaluation of biogas volumetric flow rates, which are produced during the anaerobic degradation of different substrates. The parameters measured are gas production (biogas or methane) and the substrate degradation rate. From this we obtain information about the biogas potential of the substrates and determine the comparative increase in biogas yield as a result of the ultrasonic treatment (AMPTS, Bioprocess Control).

Dry solids, chemical oxygen demand, nitrogen concentration

We routinely determine water chemistry parameters of the samples according to DIN 38414: Dry solids and volatile solids concentration. Chemical oxygen demand (COD) and nitrogen concentration are determined by photometry.

Service

To ensure that you also feel well cared for in case of a repair or technical query, we provide a continuously available service in order to guarantee smooth operation.

Through our worldwide service and sales network, we are available for you anywhere and anytime you need us and can flexibly respond to your ideas and wishes. Our technical staff is always ready to ensure optimum and permanent operation for you.

Contact